Processing ability: 2-120 t/h

Feeding size: ≤15-≤30mm

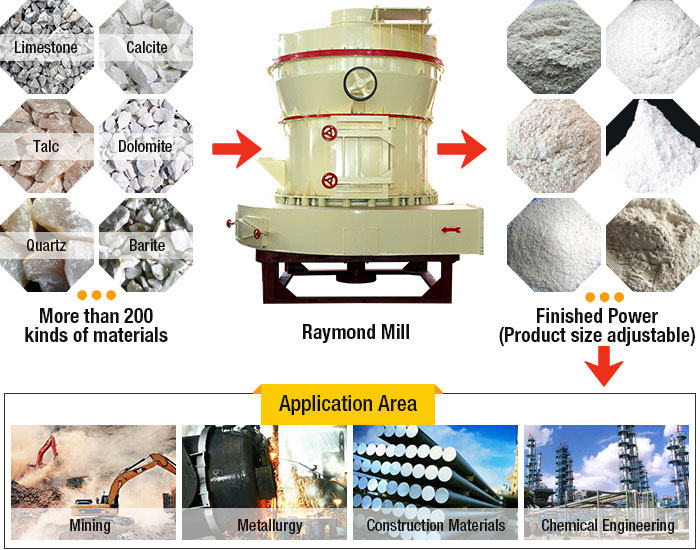

Applied material: barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite.

Raymond mill is also called Raymond roller mill, which is the commonly used for milling equipment. It is mainly used for fine powder processing of more than 280 kinds of materials such as barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, insulation materials and non inflammable and explosive minerals with not more than 9.3Mohs hardness and below 6% high humidity in chemical industry, construction industry and other industries. Raymond mill also has other names, such as Raymond pendulum mill and Raymond grinding mill.

Raymond mill is mainly composed of host machine, blower, analysis machine, finished product cyclone separator, piping device, motor and other components. The host is composed of machine frame, wind inlet volute, blade, roll grinding, grinding ring, cover and motor. The auxiliary equipment includes jaw crusher, bucket elevator, electromagnetic vibration feeder and electric control cabinet, customers can choose flexibly according to the actual production situations.

1. Relatively small occupied area, strong system, whether it is from the rough processing of raw materials, transportation, milling and the final packaging, it can become an independent production system.

2. High screen through rate, which is up to 99%.

3. The transmission device of the host adopts closed gearbox and belt wheel, which has smooth transmission and reliable operation.

4. Important parts are made of high quality castings and extrusions manufacturing, the fine craft and rigorous process ensures the durability of the whole set of equipment.

5. Electrical system of Raymond mill adopts centralized control, the working shop basically can realize unmanned operation, convenient maintenance.

Hongxing Machinery is experienced in the research and development of Raymond mill, which has high production efficiency and excellent performance. The Raymond mill price of our company is the most reasonable among mining equipment manufacturers in China. Welcome to make an enquiry!

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Output Size(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Ring Diameter(mm) | 1770 | 1400 |

| Roller Diameter(mm) | 450 | 410 |

| Roller Height(mm) | 250 | 190 |

| Main Motor(kw) | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Analyzer Motor | YCT250-4A-18.5 | YCT200-4B-7.5 |

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |