Mobile crushing plant is also called mobile crushing station, portable crushing plant. It is used in construction waste disposal, mining, coal crushing, building materials production and other industrial fields. What this equipment can process are construction waste, quartz, river gravel, basalt, cement clinker, limestone, granite, gypsum, dolomite and other over 200 kinds of stone and rocks.

Mr. Rafkul in Ethiopia is a manager of a stone processing plant. His company decided to introduce a granite crushing plant to meet the increasing granite market demand, which is also at the government's call. Crushed granite is mainly used for road building. He searched on the net and got Hongxing Machinery. When got the details of the working environment of the granite crushing plant as well as his requirements including the feed size, discharge size, etc., HXJQ engineer recommended a suitable granite mobile crushing station.

Here are some details of this granite mobile crushing plant in Ethiopia.

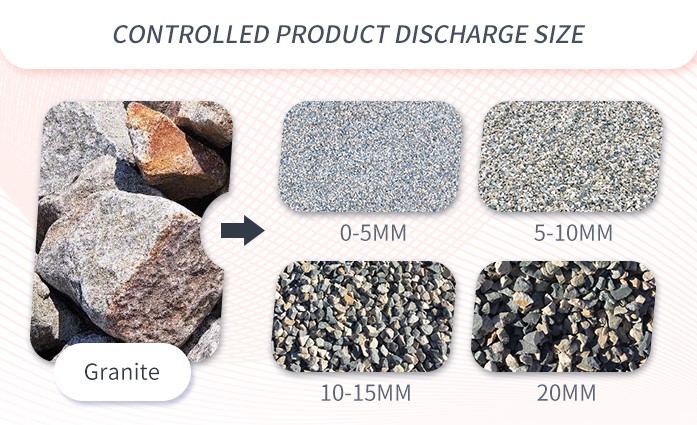

Processed material: Granite

Feed size: about 450mm

Discharge size: 5-10mm, 10-15mm, 20mm

Capacity: 150TPH

Controlled product discharge size

In this case, crushed granite is used for road building. Besides, granite is used in construction, building decoration when intermediate crushed or fine crushed. It is also one of the raw materials in cement production.

This mobile crushing plant is driven by a tractor. Among the equipment matched, there are the star crushing equipment-jaw crusher, intermediate and fine crushing expert-cone crusher and other corollary equipment like belt conveyor, vibrating feeder, vibrating screen and so on.

Granite Mobile Crushing Plant Site

In the granite crushing production, there are mainly coarse crushing, fine breaking, screening, conveying, etc.

A. The large granite raw materials are uniformly fed into jaw crusher by the vibrating feeder for coarse crushing. Under the pressure of moving jaw and fixed jaw, they are crushed into small pieces that meet the feed requirements of cone crusher.

B. The vibrating screen and conveyor belt work together continuously. The vibrating screen selects materials that meet the feed requirements of cone crusher. The finished belt conveyor transports the qualified to the vibrating feeder on the mobile cone crushing station. Those disqualified are returned to the jaw crusher for another coarse crushing.

C. Materials in the cone crusher are squeezed and ground to qualified particles by the eccentric shaft and rolling mortar wall.

Mobile crushing plant flow chart

Coarse Crusher-Jaw Crusher

The model of the jaw crusher matched in this production line is HD98. This type of jaw crusher's capacity can be adjusted between 110 and 350TPH, which can well meet customers' requirements. The maximum feed size can be up to 550mm, for which the block can be reduced.

The vibrating feeder is ZSW420X110. This feeder guarantees a continuous material feeding and stable performance. Other corollary equipment can be selected based on your need like side belt extractor, generator set and iron remover.

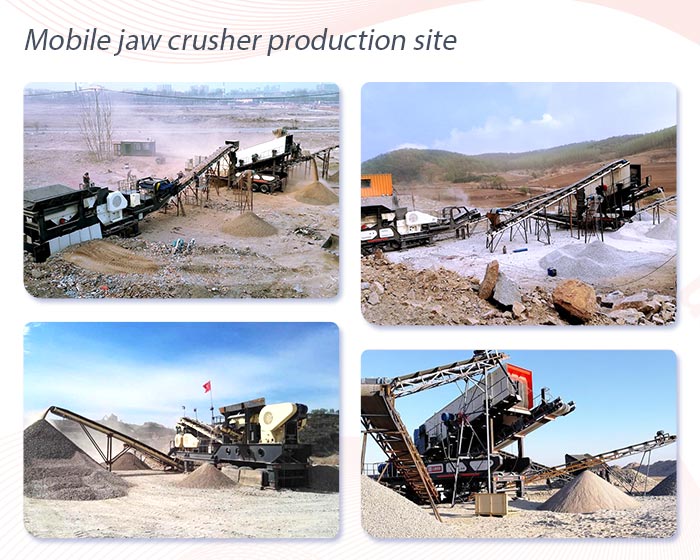

Global Hongxing mobile jaw crusher production sites

Fine Crusher-Cone Crusher

The model of the cone crusher is GYS400. According to demands, different types of cavities are available. The capacity is between 40 and 400TPH. Besides, 3YK2160 vibrating screen is equipped to work together with discharge belt machine and return belt machine to screen out the disqualified materials for another crushing. Finish belt conveyor takes charge of the transportation of qualified products to the storage.

To decrease the environment pollution, crushing plant from Hongxing Machinery is equipped with dust-removing device and noise-reducing device.

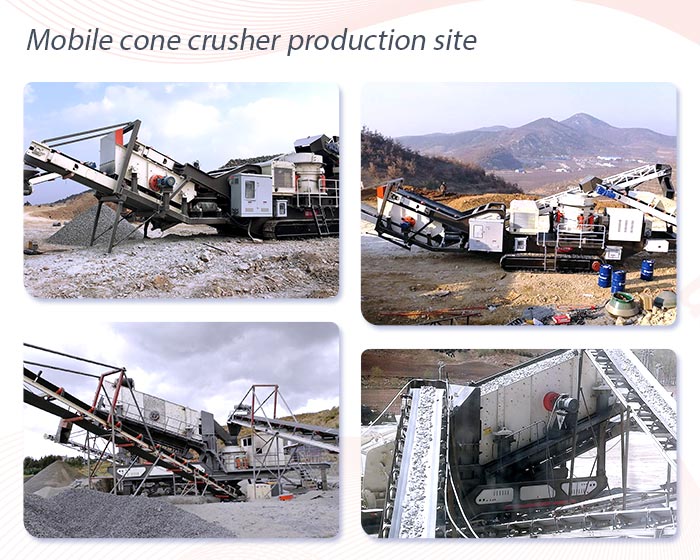

Global Hongxing mobile cone crusher production sites

Thank you for offering a suitable crushing plant with the profession of Hongxing Engineer Alan. This granite mobile crushing plant has worked for us for about 3 years. So far, each of equipment in this mobile crushing station is playing its part stably, which is a great satisfactory.

Jaw crusher is equipped with a mask, which is to reduce the noise pollution. In addition, this hydraulic cone crusher produces uniform granite particles, which is very popular among my customers. What shall be mentioned is that this portable crushing station improves the efficiency to a higher extent, reducing the transportation cost of raw material.

Hongxing Engineer and our global customers

In fact, the customer contacted a number of granite aggregate equipment manufacturers, many manufacturers recommended to him the fixed granite aggregate production line. But now he feels very lucky that he chose Hongxing mobile crushing station.

In a later conversation with Alan, Mr. Rafkul said that the terrain of the granite aggregate plant was a bit of complex and they had a lot of trouble getting the equipment in. Trucks were not able to drive into the granite mining site, but the two mobile crushing stations were able to get in easily, saving plenty of time. Because of the integrated structure, these two units have saved a lot of electricity over the one-year operation.

While, actually, they did worry about the mobile crushing station operation in the early stage. They worried that this new technology is not mature, and maintenance costs will be very high. However, the failure rate is much lower than that of the equipment they introduced before, which saves a lot of maintenance costs.

It is worth mentioning that the cost of this granite aggregate production line has been fully recovered in the first half year after it was put into operation. At present, their customers all like the size and shape of the granite aggregate produced, and the aggregate production plant is in a good state of profitability.

Customized corallory crushers of mobile crushing plant

At present, there are many kinds of crushing equipment in the market. Customers often have no ideas on how to choose a suitable machine. Here are some suggestions for reference only.

If the crushing environment is mostly flat terrain or crushing is complete in the fixed location, fixed crusher can meet the requirements. Mobile crushing station is not the only choice.

If you need more convenient and faster stone crushing equipment, or fixed crusher does not meet the requirements of stone crushing plant terrain, or you need to frequently change the crushing site, mobile crushing station will be a better choice for you.

When selecting a mobile crushing station, your own budget, feeding size requirements, discharge requirements, processing capacity and so on shall be taken into consideration. In general, after providing detailed project information, professional engineers will offer you the appropriate and customized solutions.

As a professional mobile crushing station manufacturer, Hongxing Machinery has accumulated about 35-year experience. Over 360 skilled experts are at your service to offer global customers customized crushing solutions. We have models of mobile crushing plants for sale to meet your need. For more details of mobile crushing plant selection and the skills of maintenance, please contact Hongxing engineers online or email us.