Capacity: 10-585 t/h

Rotate speed: 200–530 r/min

Diameter: 240–850 mm

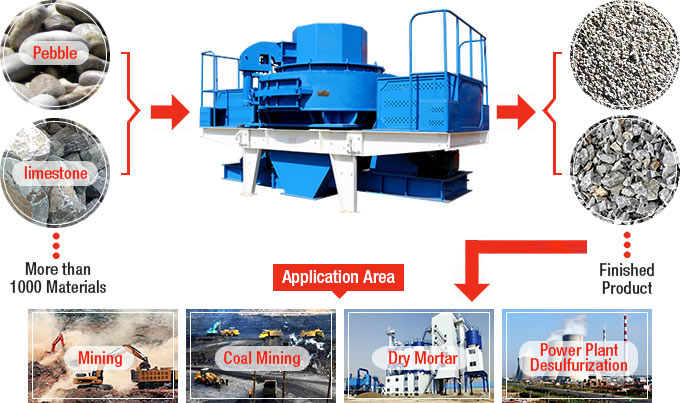

Applied material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone.

Sand making machine can be used to handle some materials such as pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc.

Sand maker is mainly used for artificial sand making. In addition, it is suitable for the crushing and plastic of soft, hard and super hard materials, which is widely applied for all kinds of ores, cement, refractory material and bauxite clinker. Especially for carborundum, silicon carbide sintered bauxite, beautiful sand as well as other hard, super hard and abrasive resistant materials; it has higher yield and efficiency than other types of crushers.

The material from feeding hopper enters into sand making machine, which can be divided into two parts by sub-feeder, one part enters the high-speed rotating impeller from the middle place of impact crusher, and then the impeller can be rapidly accelerated whose speed can reach up to hundreds of times of the gravitational acceleration, and the material must be far away from channel of the impeller in a speed of 60-70m/s. those materials which is being crushed in the cabinet so many times can reach the purpose of fine crushing at last. And those crushed material is discharged from discharging part. In this crushing operation, the material is crushed by each other, which is not connecting with the metal, which can decrease the pollution and then prolong the service life of mining machine.

1 Simple structure, high efficiency and energy saving.

2 Convenient installation and repair, low operation cost.

3 High crushing efficiency, coarse and fine crushing function.

4 Strong uncrushed materials through ability, less affected by the moisture content of materials, the water content is up to 8%.

5 It can crush medium and super hard materials (such as corundum, sintered bauxite, etc.).

6 Excellent grain shape, cubic shape, little iron pollution.

7 The materials lining in the impeller and vortex dynamic crushing cavity has greatly reduced the cost of wear parts and maintenance workload.

| Model specification |

Max.feeding size (mm) |

Power (kw) |

Rotation speed of impeller (r/min) |

Capacity (t/h) |

Overall dimension (L×W×H) (mm) |

| HX-06 | 35 | 2P 37-55KW | 2000-3000 | 10-30 | 2500×1620×2600 |

| HX-07 | 45 | 4P 55-75KW | 1500-2500 | 20-55 | 2700×1760×2800 |

| Model specification |

Max.feeding size(mm) |

Capacity (t/h) |

| HX-06 | 35 | 10-30 |

| HX-07 | 45 | 20-55 |