Processing ability: 2-120 t/h

Feeding size: ≤15-≤30mm

Applied material: Cryolite, barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite.

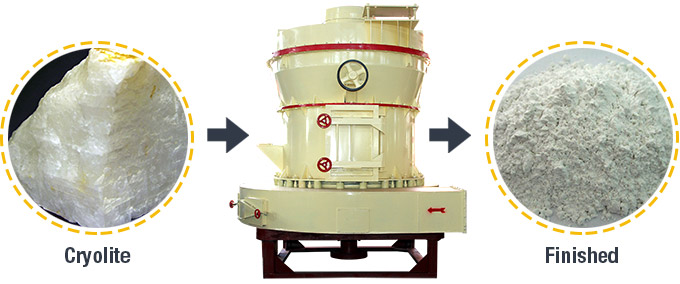

Cryolite is a kind of mineral with white and light brown color, glass luster and grease gloss. With high use value, cryolite is used to produce fluxes, opacifiers, metal fluxes and insecticides. The grinded cryolite has a wider application range. Cryolite grinding mill of Hongxing Machinery makes grinding operation for cryolite.

According to our comprehensive analysis, the main factors affecting product prices consist of product cost, market competition, consumer psychology, the national price policy and other factors.

1. Production Cost

Production cost is the base of production price. The lower manufacture cost is conductive to the affordable production cost; vice versa.

2. Market Competition

More intensified market competition has the greater impact on equipment price. In this case, the price of equipment will be lower; vice versa.

3. Consumer Psychology

Consumer psychology will also affect the consumer behavior and purchasing behavior. Therefore, most of companies will take into account of the customer psychological factor.

Hongxing Machinery whose equipment is strongly favored by customers is the professional cryolite grinding mill manufacturer in China.

1 Hongxing Machinery has a large production scale, in which case the input cost of the single equipment will be less and the price of equipment is relatively low.

2 With large production power, Hongxing Machinery makes a low scheduled profit value to its equipment.

3 Hongxing Machinery has a scientific and strict management system. Without the consumption of time and human resource, Hongxing Machinery has a low production costs.

It is your wise choice to buy cryolite grinding mill form Hongxing Machinery. Consulting email: sales@hxjq.com

| Parameter Model |

Raymond mill62 | High strength66 | High strength76 | High strength87 | High strength92 | High strength93 | High strength97 | Raymond mill4119 | Raymond mill4525 |

| Feeding size(mm) |

<15 | <15 | <20 | <25 | <25 | <25 | <25 | ≤25 | ≤30 |

| Size of finished product(mm) |

0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.044 | 0.173-0.044 |

| Shift output of different material fineness(t) |

0.6-9 | 1-20 | 1.5-25 | 2.8-33 | 3-36 | 3.5-40 | 4-52 | 8-78 | 16-176 |

| Rotate speed of central shart(r/min) |

274 | 190 | 170 | 161 | 148 | 140 | 130 | 105 | 82 |

| Diameter of pulverizing ring(mm) |

525 | 725 | 850 | 907.5 | 973 | 1006 | 1050 | 1400 | 1770 |

| Diameter of pulverizing ring(mm) |

150 | 210 | 250 | 270 | 300 | 300 | 310 | 410 | 450 |

| Height of pulverizing roller(mm) |

100 | 150 | 150 | 150 | 160 | 160 | 170 | 190 | 250 |

| Main Motor(kw) | 7.5 | 15 | 18.5 | 22 | 30 | 30 | 37 | 75 | 132 |

| Fan Motor | 4-5.5 | 4-11 | 4-15 | 4-18.5 | 4-22 | 2-22 | 4-37 | 4-75 | 4-132 |

| Analyzer Motor | 6-1.1 | 6-2.2 | 6-2.2 | 6-2.2 | 6-2.2 | 6-3 | 4A-5.5 | 4B-7.5 | 4A-18.5 |

| Parameter Model |

Feeding size(mm) |

Size of finished product(mm) |

| High-strength97 | <25 | 0.173-0.033 |

| High-strength93 | <25 | 0.173-0.033 |

| High-strength92 | <25 | 0.173-0.033 |

| High-strength87 | <25 | 0.173-0.033 |

| High-strength76 | <20 | 0.173-0.033 |

| High-strength66 | <15 | 0.173-0.033 |

| High-strength62 | <15 | 0.173-0.033 |

| Raymond mill4119 | ≤25 | 0.173-0.044 |

| Raymond mill4525 | ≤30 | 0.173-0.044 |