Processing capacity: 5-2200t/h

Feeding size: 125-250mm

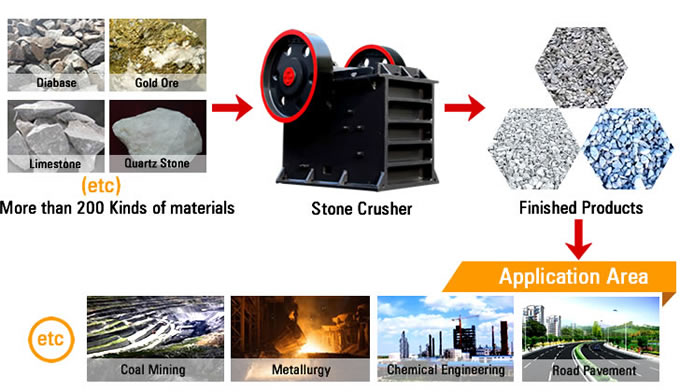

Applied material: limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

A stone crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Stone crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

In general, stone crushers can be divided into several types, namely, jaw crusher, impact crusher, cone crusher, hammer crusher, etc.

In industry, stone crushers are machines which use a metal surface to break or compress materials. Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations.

Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing.

Hongxing stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large or small primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, Hongxing Machinery can supply the right crusher as well as complete crushing plant to meet your material reduction requirements.

If you want to know the price of our machine, please leave a message in the form below or contact our online customer services.

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.