Processing capacity: 8-800m³/h

Max. feeding size: 400mm

Screen size: 4-100mm

Motor power: 5.5-22×2kw

Vibrating screen is a kind of screening equipment which relies on different amplitudes to screen out materials with different granularities and then move to the next working procedure. The difference between circular vibrating screen and linear vibrating screen is that circular vibrating screen is doing circular motion, which is a new type of multi layers and efficient screening equipment.

Vibrating screen is the essential screening equipment in all kinds of sand production lines, which is mainly used for the screening of dry materials in metallurgy, coal, ore and other materials. It is widely used for products classification in mining, building materials, transportation, energy, chemical industry and other industries. Vibration screen also has other names, such as vibratory screen and vibrating screen machine.

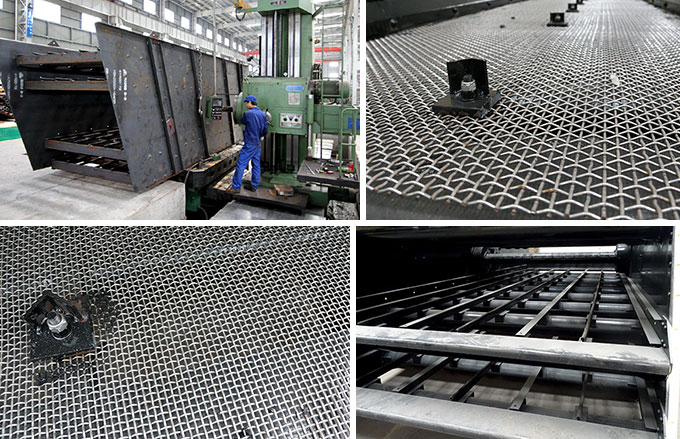

Vibrating screen is mainly composed of the screen box, vibration exciter, suspension (or supporting) devices, electric motors, etc. Motor drives the spindle to rotate through the belt. Due to the unbalanced centrifugal inertia force of heavy objects in the vibration exciter, the vibrating screen box will get vibration force. Changing the exciter eccentric weight can get different amplitude.

Vibrating screen adopts eccentric block structure, which has simple structure; it can be equipped with the feeding box, which can not only increase the effective screening area of the vibration screen, but also prolong the service life of the screen feeding end; the transmission part increases the intermediate bearing seat to protect the motor, and prolongs the duration of motor. The adjustment of screen angle can be realized by changing the height of spring frame position.

Circular vibrating screen is single-axis circular-movement inertial vibrating screen, whose working depends on inertial motor and inertial strength produced by eccentric plate. Because of the vibration of screen box, the materials are thrown out, so that materials of certain size go through the screen mesh, and the screening aim is realized. Since the magnetic exciter is installed on the gravity center of screen box, the two long elliptical axis form a shape like a Chinese character, and the upper of long elliptical axis at inlet end is in the same direction with the outlet, which favors the spread of materials which are at the screen box. However, the upper of long elliptical axis at outlet end is opposite to the direction of the outlet, which can reduce the movement speed of materials, and help the difficult-screened materials go through the screen mesh. What's more, the effective area of screen is increased because of the elliptical screen surface; as a result, the processing capacity is promoted.

1. It adopts the cylinder type eccentric shaft vibration exciter and partial block adjusting amplitude, which has convenient use and maintenance.

2. Its spring steel woven wire screen or punching sieve has long service life, which is not easy to cause blockage.

3. Rubber vibration isolation spring has long service life, low noise and stable resonance zone.

4. Reliable structure, strong exciting force, high screening efficiency.

5. Small vibration noise, durable, easy maintenance.

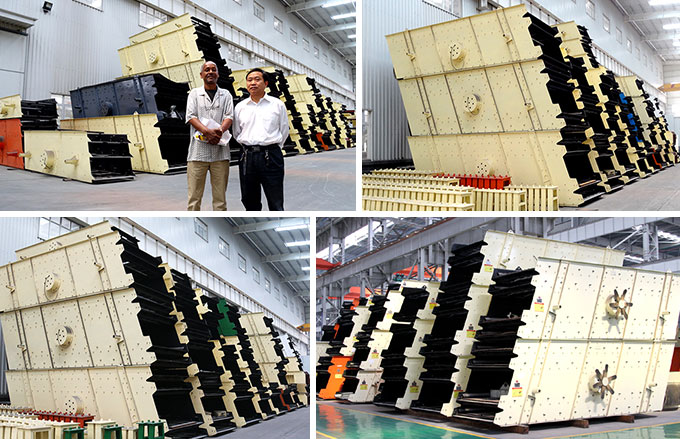

When it comes to vibrating screen price, Hongxing Machinery is the most favorable. We have years of vibrating screen production experience, and the screen equipment of our company has latest technology, high efficiency and convenient maintenance. If you want to know more information, please chat with us online or leave us a message, and we will answer you with great pleasure!

| Model | Sieve Layer | Sieve Area (㎡) |

Mesh Size (mm) |

Max.Feeding Size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Sieve Obliquity (°) |

Sieve Specification (mm) |

Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3530×1885×920 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3675×1885×1320 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4230×1990×920 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4375×1990×1320 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5355×2195×1030 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 6055×2195×1740 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6195×2195×2120 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6515×2555×1370 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6655×2555×1750 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6790×2555×2130 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7200×2945×1580 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7340×2945×1980 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7490×2945×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7200×3200×1580 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7340×3200×1980 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7490×3200×2380 |

| 2YK2866 | 2 | 31 | 5-100 | 200 | 70-650 | 970 | 6 | 6P 37 | 20 | 2800×5600 | 6950×3610×1790 |

| 3YK2866 | 3 | 47 | 5-100 | 200 | 80-700 | 970 | 6 | 6P 45 | 20 | 2800×5600 | 7130×3610×2270 |

| 4YK2866 | 4 | 62 | 5-100 | 200 | 90-750 | 970 | 6 | 6P 55 | 20 | 2800×5600 | 7300×3610×2750 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 970 | 6 | 6P 37 | 20 | 2800×6500 | 7850×3587×1790 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 970 | 6 | 6P 45 | 20 | 2800×6500 | 8025×3587×2270 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 970 | 6 | 6P 55 | 20 | 2800×6500 | 8200×3587×2750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve Area (㎡) |

Processing capacity (m³/h) |

| 2YK1230 | 2 | 7.2 | 12-78 |

| 3YK1230 | 3 | 10.8 | 13-80 |

| 2YK1237 | 2 | 8.88 | 15-86 |

| 3YK1237 | 3 | 13.32 | 16-90 |

| 2YK1548 | 2 | 14.4 | 22.5-162 |

| 3YK1548 | 3 | 21.6 | 22.5-162 |

| 4YK1548 | 4 | 28.8 | 22.5-162 |

| 2YK1854 | 2 | 19.44 | 32-312 |

| 3YK1854 | 3 | 29.16 | 32-312 |

| 4YK1854 | 4 | 38.88 | 32-336 |

| 2YK2160 | 2 | 25.2 | 50-475 |

| 3YK2160 | 3 | 37.8 | 50-475 |

| 4YK2160 | 4 | 50.4 | 50-497 |

| 2YK2460 | 2 | 28.8 | 65-550 |

| 3YK2460 | 3 | 43.2 | 70-620 |

| 4YK2460 | 4 | 57.6 | 80-680 |

| 2YK2866 | 2 | 31 | 70-650 |

| 3YK2866 | 3 | 47 | 80-700 |

| 4YK2866 | 4 | 62 | 90-750 |

| 2YK2873 | 2 | 39.2 | 70-680 |

| 3YK2873 | 3 | 58.8 | 80-720 |

| 4YK2873 | 4 | 58.8 | 90-950 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.